Extraction of Welding Fumes and abrasive Dust with a central Dust Collector System - Cartridge Filter0 pages

Welding fumes are complex mixtures of

substances made of metal oxides, silicates

and fluorides, which occur during machining

procedures, such as welding, thermal cutting

and related processes such as soldering, thermal spraying and flame hardening. These fumes

arise if metallic materials are heated beyond

boiling point, changed into gases, which then

cool down in the air and condense into ultrafine particles. These particles, whose diameter

is almost exclusively less than 1 m (<0.001mm!),

should be categorised as very hazardous to health

because they can penetrate the pulmonary alveoli

when inhaling. In higher concentrations or with

frequent exposure, these harmful substances can

lead to immediate symptoms (vertigo, headaches, “metalworker’s fever”), chronic obstructive

respiratory diseases (chronic bronchitis, asthma,

lung cancer) and damage to the central nervous

system (Parkinson’s disease).

According to the ordinance of Hazardous Substances 98/24/EC, employees must be protected

from hazardous substances and welding fumes

are declared as such a substance. In Germany, the

general threshold for alveolar dust is 3mg/m³ (see

Technical Rules for Hazardous Substances TRGS

900). As a general rule, pollutant concentrations

can occur in the breathing zone of the welder,

which can exceed the guidelines many times over,

when not using any ventilation measures - such as

extraction systems.

For high-alloyed steels, which contain more than

5 percent by weight in total of alloying elements

such as chrome, nickel and manganese, even

lower thresholds are compulsory for the work

environment of the employee. In this case, recirculated air operation of the filtered air is strictly

not permitted. Notwithstanding this principle, the

air extracted in a working area may be returned

there if it is sufficiently cleaned of such substances

using official procedures or those recognised by

Employer‘s Liability Insurance Association (e.g.

safety filter H13 as an afterfilter or energy recovery using a heat exchanger) or equipment (e.g.

W3-certified equipment).

Information on the state of technology relating

to the subject of “welding fumes” can be found in

BGR 220 , TRGS 558 and TRGS 560.

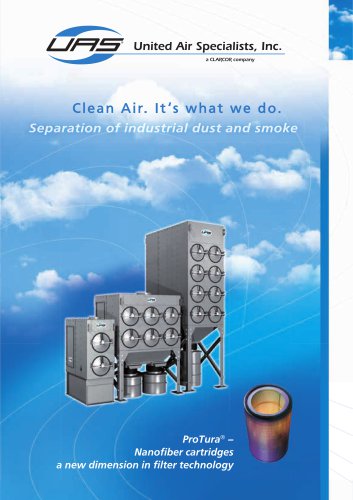

SFC filter cartridges

Problem

Zambelli Technik is a metal-working SME in the

Czech Republic, which enjoys a good reputation

as a manufacturer of ovens and chimneys and

as a supplier of the automobile industry. The

export-focused company has grown strongly in

the last few years and has successively expanded

its production capacities as a result of this. During

production, both welding fumes and abrasive dust

arise as part of the procedures.

The harmful substances should be extracted via

a central filter system, which should preferably be installed outside the production hall. The

filtered air should be returned to the hall during

the heating period via a summer/winter set-up

in order to use fewer resources and save heating

costs.

In addition welding fumes are classified as combustible, because during metal processing, i.e. when

sanding, ignition sources cannot be excluded,

resulting in a piping and filter fire. Conventional deflector plates and diversion offer no definite protection here, meaning that fire protection

tasks must be taken into consideration during the

system planning.

Solution

As described in the info box, approx. 99% of

the particles of welding fumes are smaller than

1 m and put the highest demands on the filter

medium. On one side, the filtration of ultra-fine

harmful substances must be reliable in order

to guarantee that the workplace and clean air

concentrations are at least below the existing

thresholds. However, on the other hand, moderate pressure losses should exist during long

service life of the filter cartridges in order to facilitate low operating costs.

Client: Zambelli Technik, spol. s.r.o, www.zambelli.de

EX TR AC TION OF WELDING FUMES AND ABR ASIVE DUST

WITH A CENTR AL DUST COLLEC TOR SYSTEM - CARTRIDGE FILTER

Extraction of Welding Fumes and

abrasive Dust with a central

Dust Collector System - Cartridge Filter

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید