SLF news 20120 pages

+ + + aktuell+ + +

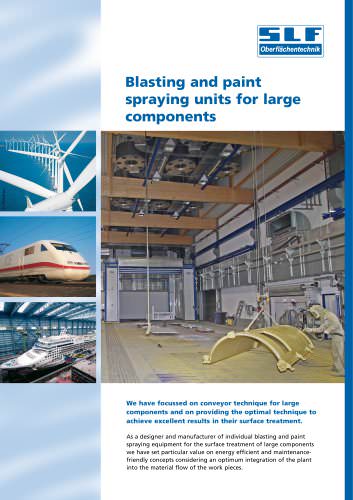

Strahlen – Lackieren – Fördern – Innovative solutionst

Dear Readers,

New ideas and inventions are the

driving force of most economies. This

paraphrase from the famous economist

and Nobel prize winner, Robert Solow,

can also be applied to a medium-sized

company.

Surface preparation at Lufthansa Technik AG and

LMB with the new media blast robot ReCo-Blaster®

Only by continuous efforts in the further

development of its own products as well

as redesigning those products to make

them more efficient and economical can

a company sustain its long-term future.

Focussing efforts on the improvement of

a product will lead to deserved attention.

A dynamic atmosphere in innovative

companies attracts good employees.

Such an atmosphere motivates and

inspires employee participation.

Based on this company philosophy we

have enhanced our equipment over the

years. Our success has proved us right.

Many of our customers have benefited

from SLF’s surface treatment techno

logy and have come to appreciate it.

An example is our media blast robot

ReCo-Blaster® that has already demonstrated its effectiveness.

The dark radiator technology “DARC”

(Dark Radiation Convection) developed

by us represents a revolution in the

enamelling process of powder coated

components. Even on work pieces with

different sheet metal thicknesses (from

3 to 100 mm) the powder is precisely

burned-in whilst maintaining a high

quality finish.

We believe the ability to maintain innovation over generations, and call upon

it again and again from our employees,

will lead to our company’s success and

business development in the long-term.

Issue 3 · 2012

Blastroom with media blast robot ReCo-Blaster®

I

n the course of regular checks, aircraft

landing gear is subject to crack detection. For this purpose they are completely

disassembled and the paint is removed by

blasting.

For this paint stripping process, SLF’s

blasting robot ReCo-Blaster® has recently

been commissioned at Lufthansa Technik

AG in Hamburg.

Previously the landing gear components

were prepared by use of a manual blasting

cabinet.

During this process the operator stood

outside the cabin and fed the blast nozzle,

which was fixed to a lance with a length of

up to 2 m, through arm holes towards the

work piece, i.e. a laborious and exhausting

working process, especially for complex

work pieces.

The manual blasting cabinet is now obsolete!

Blasting of work pieces is now performed fully automatically by the ReCoBlaster® developed by us! The robot

not only replaces the laborious manual

operation, but also makes it possible to

reproduce the blasting process once it

has been programmed by means of the

“Teach-In-Mode”. Therefore, the ReCoBlaster® is an economically viable and

worthwhile investment, particularly for

parts treated in series.

The use of a twin-chamber pressure

blast pot allows continuous blasting without interruption. During the blasting process, blast pressure and media flow are automatically adjusted and controlled.

The ReCo-Blaster® fully automatically

blasts the outer surface of the work pieces

with a 19 mm sized blast nozzle. The inner

side is tackled with an up to 2.5 m long

blasting lance that can be attached to the

robot arm.

Eight axes ensure an optimal free movement of the robot. In order to minimize

wear on the robot, its shoulder and wrist

actuators, as well as the supply cable of

the robot arm, are integrated in the robot

housing. Double sealing protects the vertical axis against abrasive and dust.

Operation of the robot and programming of work piece parameters is performed by means of two joysticks. As the

joysticks are fixed to a moveable control

panel, programming of the robot movements (without abrasive) is possible inside

the blastroom or from outside via a viewing window.

Teaching from the outside can also be

performed during the running blasting

process. The robot control which is used

in connection with the joysticks allows for

very easy programming of the sequence of

movements.

Foto: Daniel Morsey

Robot arm

Compared to a conventional multiaxis control, the operator does not have

to control the movement of the indivi

dual axes, but only the shifting and position of the blast nozzle in relation to the

work piece.

Another example is at a large steel

component preparation company Logaer

Maschinenbau GmbH in Leer, Germany

where a ReCo-Blaster® will soon be used for

blasting prior to the paint spraying process.

By acquiring a ReCo-Blaster® our customers have taken into consideration all

aspects of profitability, ergonomics and

automation with an optimal occupatio

nal health and safety aspect. The result is

a consistent, reproducible blasting quality

due to the automatic control of the variable

parameters.

Fritz Gaidies and Michael Bahlinghorst

For this reason, after the retirement of

our former managing partner HeinzGeorg Vollmer, the technical responsibility of our company was transferred

to Mr. Michael Bahlinghorst. He has

worked in a leading position in our

company for many years and since

the beginning of this year has become

a member of the management partner

team. Together with the managing partner Fritz Gaidies he now controls the

affairs of our company.

Best Regards

Exterior view of a blastroom with ReCo-Blaster®

Fritz Gaidies

Michael Bahlinghorst

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید