"

00

Analytical Instrumentation

article

The On-Line Detection of Oxides of Nitrogen in Light Hydrocarbon Streams

author

by Modified Chemiluminescence Detection

and/or by Dry Colorimetric Detection

Surinder (Sandy) Thind

Applications Chemist

C. I. Analytics

www.cianalytics.com

Abstract:

Producers of high purity monomers (ethylene) have identified the

need to measure the presence of Oxides of Nitrogen (NOX) at very

low PPB levels, and take steps to avoid potentially hazardous

conditions, in the Cold Box.

NOX (NO and NO2) in the olefins processing train is a safety

concern. There is a possibility of accumulation of unstable liquid or

solid nitrogen oxide (N2O3) and nitrogen oxide-organic solids in

the cold processing equipment.

In the Cold Box of ethylene production plant at temperature,

130 C to 170 C, oxides of nitrogen may combine with dienes (gums)

and form potentially explosive nitrated resins.

During, shut down, at the time the olefins recovery train is

allowed to warm up, any cracked gas flow passing through sections

where N2O3 has deposited, will lead to the formation of extremely

hazardous conditions. This is due to the reaction of NO2 and N2O4

with heavier olefinic materials. The NO2 can react with olefinic

materials to form “gums”. These ‘gums’ formed are explosive at

cryogenic temperatures. NOX deposits represent the presence of

a powerful oxidizer in a system filled with flammable materials.

Even though, in theory, Nitric Oxide (‘NO’) is the only NOx

species that reaches the cryogenic ethylene recovery unit, it is also

required to measure other species that belong to NOX group.

If NOX levels are below five parts per billion in the cracked gas,

then accumulations would not be expected to occur. However, if

the concentration is over 30 ppb, accumulations in one form or

another are assured.

The analytical challenge of NOx in Light

Hydrocarbons Analysis:

The measurement of 1 ppb-50 ppb levels of NO in complex olefins

matrixes is a major analytical challenge. The detection is required

at 1 PPB level. This is difficult due to the presence of major

interference of the matrix and trace level contaminants at PPM

levels.

Many analytical techniques fail in this application, including

GC-Chemiluminescence and GC-PID due to lack of the required

sensitivity or specificity.

C.I. Analytics has solved this analytical problem using two

different detectors. One is Dry Colorimetery Detector and the other

is the modified GC-Chemiluminescence.

In the past, several efforts have been made to detect NO using

Gas Chromatography followed by detection using either a Photo

ionization detector or traditional chemiluminescence detector.

Both these detectors require accurate gas chromatography work

and slight variation in retention time will result in false results.

The PID can detect down to 80 PPB. The GC-Chemiluminescence (traditional detector) is not truly applicable to online work, while experienced chemists have made detections at 50

PPB level. This does not meet the analytical requirements of

measuring NOX at levels much below 50 PPB.

The new modified chemiluminescence detector by C.I.

Analytics and another field proven technique, Dry Colorimetery

method to detect NO provides a successful technical solution to

this analytical problem.

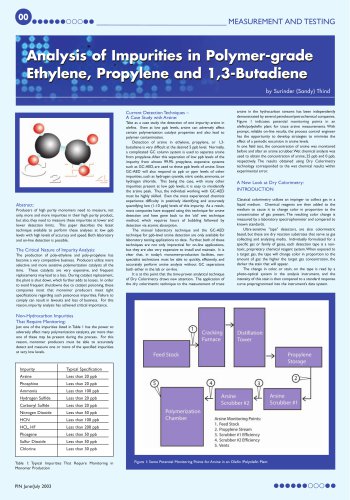

Current Detection Techniques

A Case Study with GC-PID or GCChemiluminescence:

Take as a case study the detection of one impurity:

Nitric Oxide in Ethylene.

Detection of nitric oxide in ethylene, propylene, or 1, 3 butadiene is

very difficult at the desired 1 ppb level. Normally, a complicated GC

column system is used to separate nitric oxide from propylene.

After this separation of low ppb levels of the impurity from almost

99.9% ethylene and other ppb or ppm levels of other impurities,

such as hydrogen cyanide, nitric oxide, ammonia, or hydrogen

chloride. This being the case, with many other impurities present

at low ppb levels, it is easy to misidentify the NO peak. Thus, the

individual working with GC-PID must be highly skilled. Even the

most experienced chemists experience difficulty in positively

identifying and accurately quantifying low (1-10 ppb) levels of this

impurity. As a result, most companies have stopped using this

technique for NO detection.

The laboratory technique, the GC-Chemiluminescence or GCPID technique for ppb-level NO detection is only available for

laboratory testing applications to date. Further, both of these

techniques are not only impractical for on-line applications, but

they are also very expensive to install and maintain. It is clear that,

in today’s monomer-production facilities, non-specialist

technicians must be able to quickly, efficiently, and accurately

perform NO analysis without GC separations both either in the lab

or on-line.

Using Modified GC-Chemiluminescence.

The traditional Chemiluminescence detector, for the detection of 1

PPB levels of NO requires reaction of NO with Ozone at reduced

pressure. That means there is a need for the use of a vacuum

pump. This pump will create reduced pressure in the reaction cell

of the detector. The detector response will change as the vacuum

conditions change. Plus, vacuum at the end of GC column leads to

retention time problems. If retention time is shifted, then false

results will be reported. Not to mention total failure if ethylene

reaches the detector, as ethylene will give a big response (false

peak).

The GC-Chemiluminescence detector responds to PPB levels

of ethylene. So, the choice of the GC-columns is extremely

important. Two conditions must be observed. First, the analytical

column must separate NO from ethylene. Second, the complete

system must be inert. The columns, valve, loop and connective

tubing must not adsorb NO at low levels.

All these factors have made on-line detection of NO very

difficult, even though, in some labs, good results at 50 PPB level

have been achieved.

C.I. Analytics has solved this problem. The need for use of

vacuum pump has been eliminated. The analytical system is made

inert; the photomultiplier tube has been replaced by another photo

sensitive device. The problems associated with interferences have

been reduced. The ethylene at PPM levels will not interfere. The

GC Columns are packed 1/8 inch and the detector is sensitive

down to 1 PPB level of NO.

Figure 1: CI Analytics On-Line NO Analyzer

C.I. Analytics: GC-Chemi for 20 PPB NO detection at customer

location since the year 2000.

process control engineer has the opportunity to develop strategies

to minimize the formation of potentially explosive nitrate resins in

the cold box. The results obtained using Dry Colorimetery

technology corresponded to the laboratory results, using GCchemiluminescence, within experimental error.

C.I. Analytics has developed a special formula that is deposited

on the filter tape. This tape will respond only to NOx.

A New Look at Dry Colorimetery:

Introduction

Classical Colorimetery utilizes an impinger to collect gas in a liquid

medium. Chemical reagents are then added to the medium to

cause it to change color in proportion to the concentration of gas

present. The resulting color change is measured by a laboratory

spectrophometer and compared to known standards.

Ultra-sensitive “tape” detectors are also colorimetric based, but

these are dry reaction substrates that serve as gas collecting and

analyzing media. Individually formulated for a specific gas or family

of gases, each detection tape is a non-toxic, proprietary chemical

reagent system. When exposed to a target gas, the tape will

change color in proportion to the amount of gas: the higher the

target gas concentration, the darker the stain that will appear.

The change in color, or stain, on the tape is read by a photooptical system in the analysis instrument, and the intensity of this

stain is then compared to a standard response curve preprogrammed into the instrument’s data system.

Analytical Technique

Using Dry Colorimetery Detection for

1 PPB level NOx.

The GC-Chemiluminescence detection requires more attention

than the on-line service teams has the time to devote. Is there

another technique that will give accurate results without the need

for special care? In addition, it is desired for complete safety and

prevention of explosive resins, that Total NOx be measured and

reported instead of assuming that only NO will reach the cold box.

It is at this point that the time-proven analytical technique of

Dry Colorimetery draws new attention. The application of the dry

colorimetric technique to the measurement of trace NOx in the

hydrocarbon streams has been independently demonstrated by

several petroleum/petrochemical companies. Figure 1 indicates

potential monitoring points in an olefin/polyolefin plant for trace

NO measurements. With prompt, reliable on-line results, the

Figure 2: Modern Dry Colorimetric Detection:

The C.I. Analytics System

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید