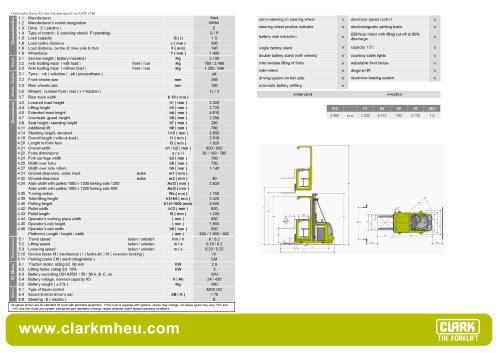

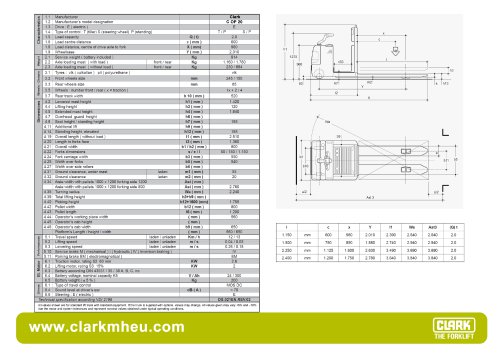

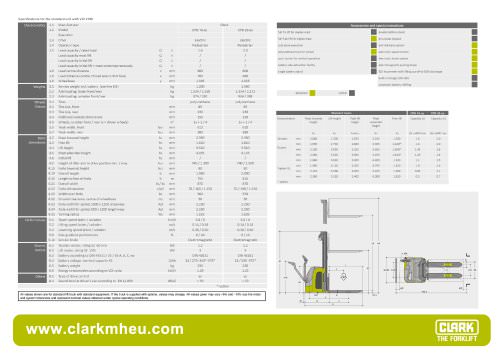

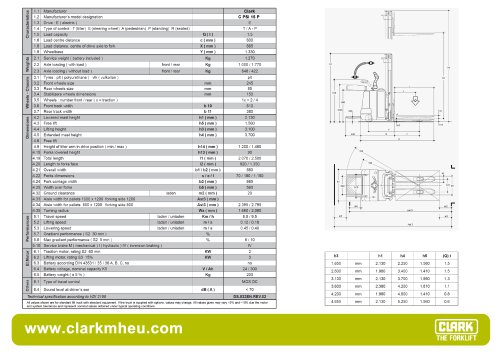

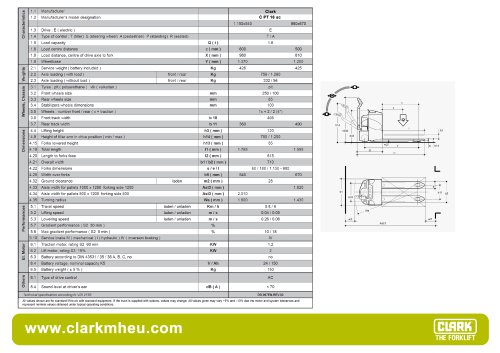

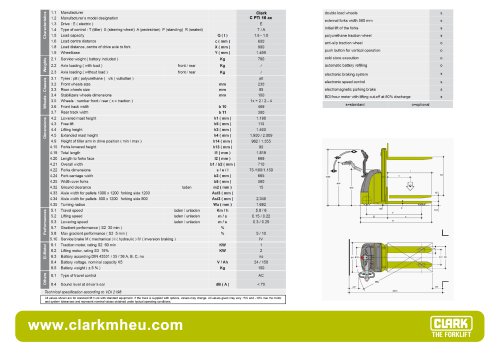

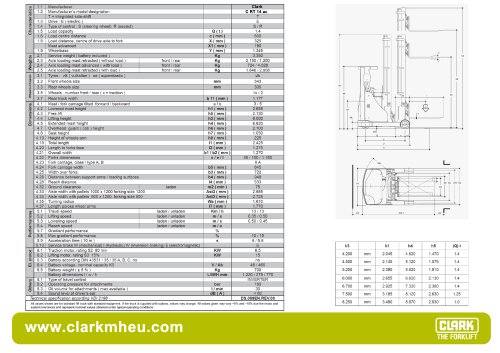

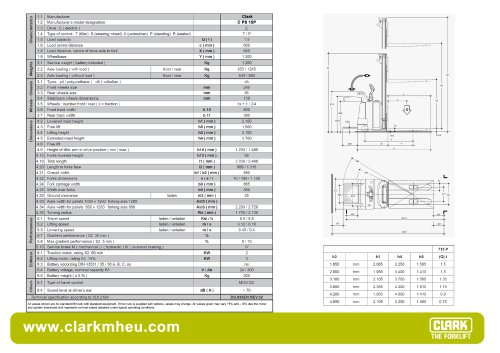

Specification sheet CLARK GEX20/25/30(s)/30L0 pages

GENERAL DATA

PRODUCT DESCRIPTION

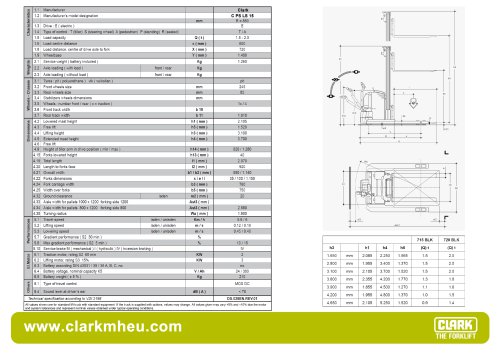

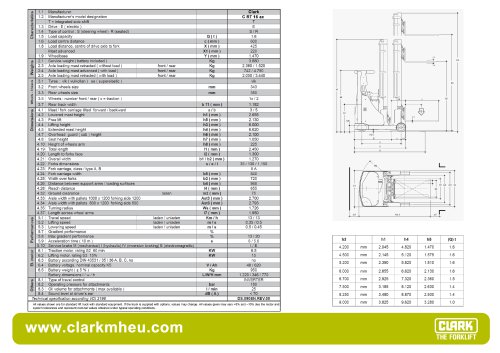

Upright table GEX 30L

Truck Capacities Capacity at different load centres

Mast type

3000

Maximum

Fork Height

(h3)

Mast

Lowered

(h1)

with load

backrest

2500

2000

1500

1000

without load

backrest

with load

backrest

without load

backrest

mm

mm

mm

GEX 20

mm

mm

mm

2015

GEX 30L

GEX 30(s)

GEX 25

1575

3234

2676

2575

1855

3794

3236

2875

2005

4094

3536

3195

The listed capacities are valid only for the standard upright in vertical position with standard

fork carriage and standard forks, up to max. lifting height of 3085 mm. The centre of gravity

of the load may be displaced by max. 100 mm against the longitudinal centre plane of the

truck. Load centre is determined from top and front face of the forks. The values are based

on a 1000 mm cube load configu-ration with the centre of gravity at the true centre of the

cube With upright tilted forward lower capacity values are valid. Attachments, longer forks,

exceptional load dimensions and higher lifting heights can reduce the capacity. Please talk to

your CLARK dealer if you require further information.

4386

3860

2530

5079

4521

2800

5384

4826

3000

5599

5041

3230

5839

5281

5170

Note:

3856

4944

4620

Load center in mm

4414

2455

4380

500

2165

3725

4165

Standard

Free Lift

(h2)

3495

6389

5831

115

115

3860

1855

5079

4544

636

1172

4320

2005

5539

5004

786

1322

4800

6019

5484

946

1482

2305

6429

5894

1086

1622

5520

2455

6739

6204

1236

1772

5740

2530

6959

6424

1311

6100

2690

7319

6784

1471

2007

2800

7589

7054

1581

2117

Maximum

Fork Height

(h3)

Mast

Lowered

(h1)

8049

7514

1781

2317

8534

7999

2011

2547

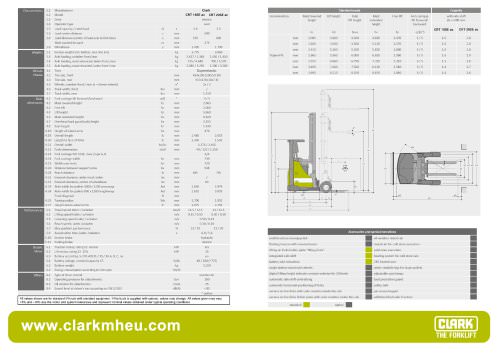

Upright table GEX 30/30s

Mast Extended

(h4)

with load

backrest

3000

3230

Mast type

Free Lift

(h2)

without load

backrest

with load

backrest

mm

Mast

Lowered

(h1)

without load

backrest

mm

Maximum

Fork Height

(h3)

Mast Extended

(h4)

with load

backrest

without load

backrest

with load

backrest

without load

backrest

mm

mm

110

110

mm

mm

mm

mm

mm

mm

mm

mm

2015

1575

3234

2612

2015

1575

3234

2682

2575

1855

3794

3172

2575

1855

3794

3242

2875

2005

4094

3472

2875

2005

4094

3542

3195

Standard

Free Lift

(h2)

2165

4414

3792

3195

2165

4414

3862

3725

2455

4944

4322

3725

2455

4944

4392

3860

2530

5079

4457

3860

2530

5079

4527

110

110

Standard

4165

2800

5384

4762

4165

2800

5384

4832

4380

3000

5599

4977

4380

3000

5599

5047

4620

3230

5839

5217

4620

3230

5839

5287

5170

3495

6389

5767

5170

3495

6389

5837

3860

5079

4483

636

1232

3860

1855

5079

4549

636

1167

2005

5539

4943

786

1382

4320

2005

5539

5009

786

1317

4800

2165

6019

5423

946

1542

4800

2165

6019

5489

946

1477

5210

2305

6429

5833

1086

1682

5210

2305

6429

5899

1086

2455

6739

6143

1236

1832

5520

2455

6739

6209

1236

2530

6959

6363

1311

1907

5740

2530

6959

6429

1311

2690

7319

6723

1471

2067

6100

2690

7319

6789

1471

6370

2800

7589

6993

1581

2177

6370

2800

7589

7059

1581

8049

7453

1781

2377

6830

3000

8049

7519

1781

Optional equipment

Pneumatic or non-marking tyres, side battery change, attachments, cabs, mini- or

multifunction levers and much more

Safety

The GEX series is CE certified and corresponds to all European safety standards for

counterbalanced forklift trucks.

2312

Triple

7315

3230

8534

7938

2011

2607

7315

3230

8534

8004

2011

3395

9019

8423

2176

2772

7800

3395

9019

8489

2176

2005

4154

3558

786

1382

2935

2005

4154

3624

786

1317

3255

2165

4474

3878

946

1542

3255

2165

4474

3944

946

1477

3530

2305

4749

4153

1086

1682

3530

2305

4749

4219

1086

1617

3760

2455

4979

4383

1236

1832

3760

2455

4979

4449

1236

1767

3910

2530

5129

4533

1311

1907

3910

2530

5129

4599

1311

1842

Talk to your CLARK dealer to find the optimum equipment for you.

2707

2935

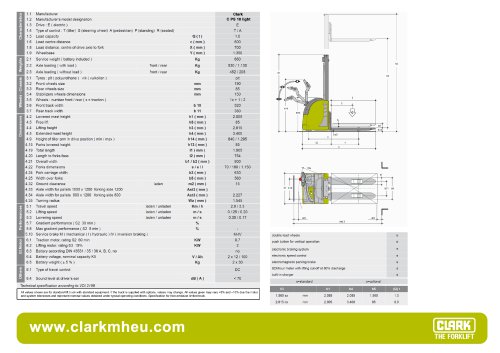

Steering system

The 101° degree angle of the steer wheels turns the GEX four-wheel forklift almost on the

2542

7800

HI-LO

Further standard equipment

Working headlights, acoustic reversing alarm, combination rear lights incorporating

brake and reverse light, paintwork in a bright safety colour „CLARK Green“, driver‘s

compartment and upright in matt black, wheel rims in white finish.

2112

3000

Upright

The clear-view uprights are available in Standard, Hilo and Triplex versions. The

interlocking profiles provide high strength and improved safety, even at high levels.

Enclosed canted rollers minimize deflection and can easily be adjusted without major

disassembly.

Tilt cylinders are mounted in spherical bushings, eliminating hydraulic seal strain,

thereby increasing the service life of the complete cylinder. An integral tilt-lock valve

prevents excessive tilt speeds and unintentional operation of the upright.

The upset forged forks ensure long service life and are hook mounted and pin lockable

to ensure accurate for positioning.

A hydraulic cushioning valve reduces upright shocks and allows smooth lifting and

lowering at all times, ensuring a long service life and less product damage. The sturdy

6-roller fork carriage features enclosed canted rollers together with adjustable side

thrust rollers, preventing carriage jamming when handling offset loads.

2002

6830

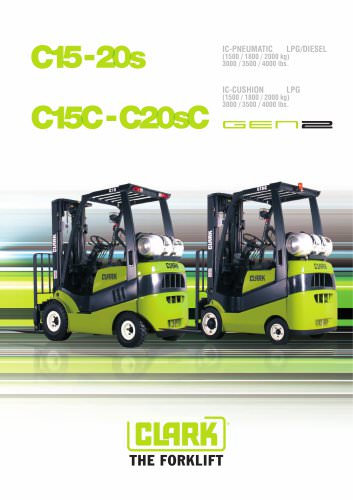

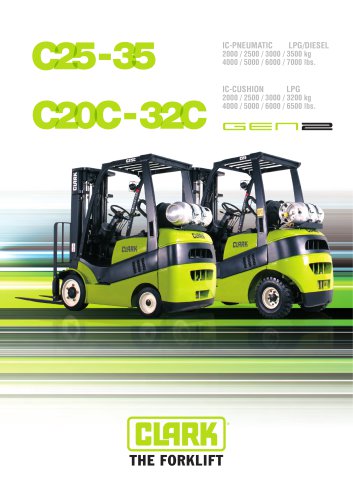

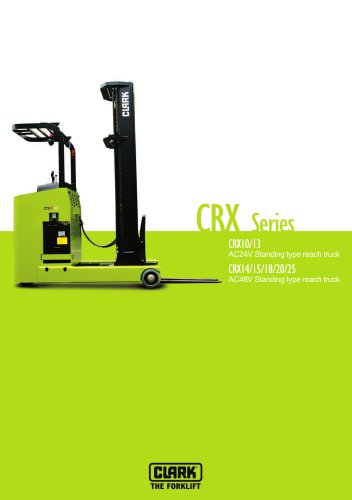

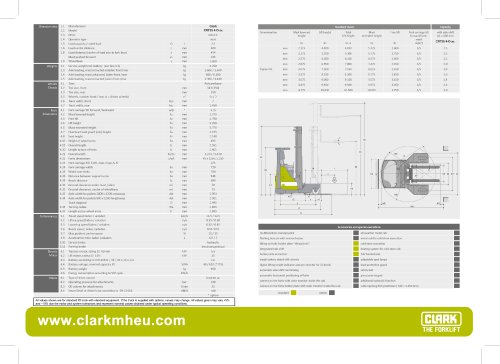

80V Electric Lift Trucks

Superelastic Tires

2.000 kg 2.500 kg 3.000 kg

1842

6100

GEX20/25/30(s)/30L

1767

5740

Brake system

Three independent brake systems (electrical, foot and parking brake) ensure increase

efficiency through improved utilisation of the battery capacity and high safety. Fully

enclosed oil-immersed multiple-disc, foot and parking brake provide constant brake

performance in all conditions.

The regenerative electrical brakes return energy to the battery during each braking

action. This process saves energy costs, reduces brake wear and extends the driving

time per battery charge.

If the driving direction is changed by operation of the direction lever, the electronics ensure gentle braking and progressive acceleration in the new direction of travel. The fully

enclosed service brakes are protected against dust, damp and aggressive particles. Use

under difficult environmental conditions is therefore possible without any problems.

The standard ramp start feature enables controlled operation of the truck on gradients

and precise handling on loading platforms.

Hydraulic system

The independent, AC powered hydraulic pump only pumps the required oil volume for

the relevant task, ensuring optimum energy efficiency and longer battery shift life.

The internal gear hydraulic pump is distinguished by especially low pump noise

combined with high efficiency. This saves energy and reduces the heat load on the

hydraulics.

The steel hydraulic tank ensures good heat dissipation for the hydraulic oil ensuring

long service life for the hydraulic components.

The full-flow return line filtration filters the oil to the tank at each reverse flow.

Large particles are filtered directly via a suction filter, thereby preventing them from

entering the oil circuit. This ensures a long service life for all hydraulic components.

1617

5520

Triple

1855

4320

Motor, drive and control

Two powerful 7.8 kW AC motors driving the front wheels and 80 Volt three-phase current technology ensure excellent acceleration and high performance. The maintenance

free AC motors ensure running costs are kept to a minimum.

The temperatures of the motors and controller are constantly monitored with the power

being automatically adjusted to prevent design limits being exceeded.

The ZAPI DUAL AC control is equipped with modern MOSFET and CAN bus technology and is located safely, high in the counterweight, where it is protected, yet easily

accessible. The motor and controller temperature monitoring devices serves to protect

your investment.

spot – similar to the three-wheel forklift. Even in this position, smooth start up and control

is maintained due to the independent front wheel drive.

Depending on the angle of the steer wheels, the speed and direction of rotation of the

front wheels is controlled in such a way that significant wear of the tyres is avoided.

When cornering, the traction speed is automatically reduced proportional to the degree

of turn.

HI-LO

Performance may vary +5% and -10% due to motor and system efficiency tolerance. The performance shown represents nominal values which

may be obtained under typical operating conditions of a machine. CLARK products and specifications are subject to change without notice.

CLARK Europe GmbH

Neckarstraße 37

D - 45478 Mülheim an der Ruhr

Tel.t 49 208 377336 0

+

Faxt 49 208 377336 36

+

email: info-europe@clarkmheu.com

www.clarkmheu.com

Lot 9655

Mast type

6830

7315

Upright table GEX 20/25

Operator’s Compartment

A large low positioned step, together with a grab handle on the drivers guard column

allows easy access to the ergonomically designed operator’s compartment. A full

width rubber floor covering in the footwell ensures a firm footing in all conditions.

The tilting steering column and an easily adjustable comfort seat, gives maximum

legroom enabling optimal adjustment to suit any driver.

The operator’s foot pedals are arranged in the automotive fashion to avoid any confusion. The fully directional operating levers move smoothly giving precise control and are

located at a perfect height to enable easy handling and a firm grip.

Essential operating data is displayed in real-time on the clear TFT LCD colour display.

Three individually programmable operating modes (Economy-Normal-Power) as well

as an additional crawl function allows you to optimally adapt the vehicle to the relevant

work situation.

Easily accessible stowage compartments as well as quick access to the hand brake and

emergency stop switch complete this impressive operator’s compartment.

1847

6370

Triple

2165

5210

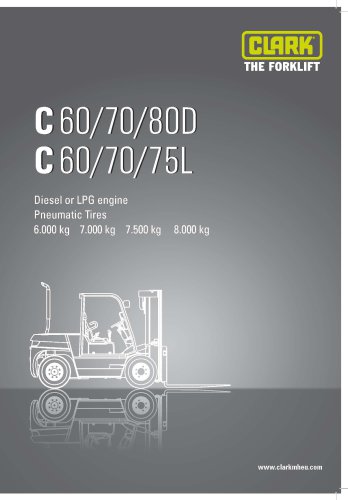

Two powerful AC motors driving the front wheels, a very sturdy design without

unnecessary plastic components and an extremely short wheelbase, distinguish the

GEX 20-30L series from CLARK. Suitable for most applications thanks to a solid ”built

to last“ construction and well thought-out driver‘s compartment.

En. 03/2011

Capacity in kg

Mast Extended

(h4)

www.clarkmheu.com

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید