Brakes for Cranes0 pages

Overhead Cranes

SITE REVIEW

Brakes

for Cranes

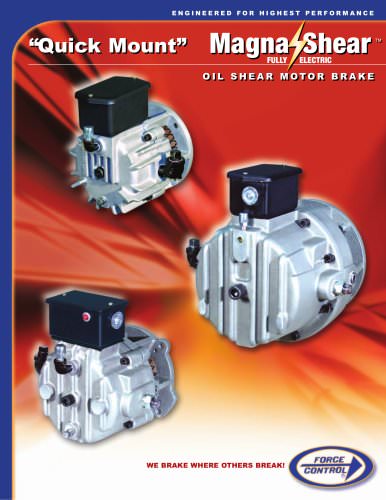

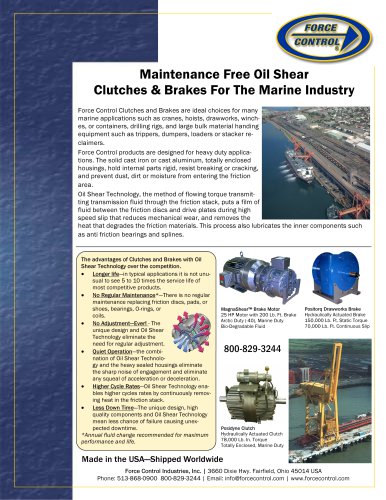

MagnaShear motor brake

from Force Control Industries.

Paint finish company opts for

oil shear brakes to reduce crane

maintenance and downtime.

Linetec previously employed dry brakes in its hoist systems,

which required more than 120 hours per year in maintenance.

Oil shear brake alternative

P

aint finish specialist Linetec, Wausau, Wis., employs a

computer-controlled hoist system to guide material through the anodize

process, eliminating any chance of manual variations in pre-cleaning,

etching, anodizing, coloring, or sealing. Each of the eight cranes in the

plant includes a 3-hp trolley motor and 15-hp hoist motor. Every motor

performs roughly 2,000 moves per shift.

The hoist system’s dry brakes were mounted on each motor for stopping

and positioning. Since these brakes have a sacrificial wear surface—the

disc—each one had to be checked weekly. In addition, each brake was

rebuilt on a quarterly basis, requiring disassembly, replacement of the disc

and solenoid, check the gap, reassembly, and start it running again.

Linetec estimates conservatively it was spending 124 hours per year on

preventive maintenance. In addition to time, the plant was spending about

$8,000 per year on maintenance parts. Because all work on the brakes

was accomplished without removing them from the motors, scissor lifts

were required to reach the motors nearly 30 feet in the air. At that height,

the ambient temperature is elevated throughout the year—especially in

summertime when the heat routinely registers in the triple-digit range.

Most maintenance work was scheduled for the weekend when the

plant was idled, but unscheduled failures while the plant was operational

created problems of another sort.

“If the brakes failed when the line was running, we’d have to shut down

production, then go get a scissor lift and the necessary tools and materials,”

said Jon Brubacher, maintenance supervisor. “Then we’d do the rebuild…It was

quite time consuming, and the line is down throughout the entire process.”

Downtime was calculated at $1,500 per hour, and these costs escalated

quickly for the company.

16 Industrial Lift & Hoist

When Bob Rhode from Linder Electric suggested an alternative

braking technology, Brubacher was intrigued. Rhode and Dave Price

of Industri/Motion brought products from Force Control Industries to

Linetec to demonstrate the differences between traditional brakes and oil

shear technology.

Linetec placed an initial order for a single MagnaShear MSB6 motor

brake, which was put into service as a trial. After six months with virtually

no maintenance and no failures, the Linetec team began formulating a

plan for a capital expenditure to replace all of its dry brakes.

“We’re very pleased with the performance of the Force Control brakes,”

said Brubacher. “We have not had a single issue with them since they

were installed. With oil shear brakes on all of our cranes and hoists, we’ve

reduced downtime significantly and increased our productivity.”

How oil shear technology works

Normal dry clutch brakes employ a brake disc or pad to engage the

load. Having no good way to remove the heat caused from engagement

between the disk and plate, this material must absorb the heat. Extremely

high temperatures will eventually degrade the friction material. As the

surface wears away and begins to glaze, the spring force is also reduced,

causing the ensuing torque fade. This leads to positioning errors, which

require adjustment or replacement of the friction surface.

By comparison, oil-shear technology includes a fluid film that flows

between the friction surfaces. As the brake is engaged, the fluid is compressed.

The automatic transmission fluid (ATF) particles in shear transmit torque to

the other side. This torque transmission causes the stationary surface to turn,

bringing it up to the same relative speed as the moving surface. Since most

of the work is done by the fluid particles in shear, by the time the surfaces

actually meet or “lock up,” wear is virtually eliminated.

In addition to transmitting torque, the ATF also helps to dissipate

heat, due to a patented fluid recirculation system. Along with torque

transmission and heat removal, the fluid also serves to continually lubricate

all components, which extends service life. Oil shear technology also

provides a “cushioned” stop that reduces shock to the drive system. Unlike

dry clutch brakes, the enclosed oil shear system is impervious to external

elements, such as wet, dusty, or dirty environments. Since the layer of oil

eliminates wear, the MagnaShear motor brake provides a long service life.

For Linetec, replacing its dry brakes with oil shear brakes has eliminated

wear and adjustment, increased uptime, and saved them money.

industrialliftandhoist.com • November 2012

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید