LOADING

DUSKOLECTORS 0 pages

نسخه متنی

"

"

| DUSKOLECTORS | |||||||||

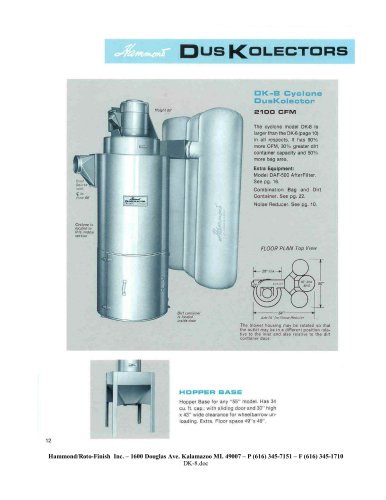

| Optional DK-655 with 55 gallon drum Hammond DusKolectors® are independent dust collectors used for isolated machines that cannot be connected to a central dust collection system, or where no central system is available. In operation, the DusKolector® draws the dirty air inside itself where the heavier particles are deposited in a dirt container at the bottom of the machine; either a tray or a 55-gallon drum. The air then goes through filters which remove the finer particles, and the filtered air returns to the room. There is no waste of energy exhausting heated or cooled air to the outside of the building. DusKolectors® are available in three models: cabinet, cyclone, and CycloPlus. Cabinet Model The cabinet model (FDK) is rated at 700 CFM , is compact, and is suitable for light or intermittent dust collection applications. Dust laden air is drawn into an expansion chamber where the heavier particles fall into the dirt pan. The air goes through a polyester pleated filter which removes the finer particles. Filtered air is exhausted back into the room. FDK-4 The cabinet model is recommended for pedestal grinders or small abrasive belt grinders. It is not recommended for collecting stringy or bulky materials, e.g. buffing link and saw dust.Cyclone Model The cyclone (DK) models range from 500 to 800 CFM. These models incorporate the centrifugal precipitation and gravitation principle. The heavier particles are deposited in the dirt container. The finer particles are captured in the bag(s). Filtered air exhausts through the bag back into the work area. Each bag has a zipper in the bottom for dust removal. The blower wheel, a self-cleaning paddle wheel, is located on the "clean air" side of the cyclone reducing wear, and is direct-driven by a 3600 RPM motor. The photos below illustrate the internal workings of the Dk, and show the optional DK-655 with 55-gal. drum for dust containment. DK internal workings CycloPlus Model The CycloPlus (CDK) models range from 5500 to 5900 CFM. These models require relatively little floor space, offer better filtration and extended cartridge life, and are suitable for a wide range of applications. During collection, primary filtration is by conventional cyclonic action. As much as 75-90% of heavy particles drop out in the dirt container. Escaping fines are captured on the surface of the pleated cartridge filter inside the DusKolector® body. Acting only as a final filter, the cartridge is not overloaded and can clean airstreams with up to 99% efficiency, and trap dust particles down to 1 micron in size.During cleaning, the reverse pulse-air jet continuously cleans the cartridge on a timed cycle. Loose particles are blown into the outer cyclone air stream and carried to the dirt container; not redeposited on the cartridge filter. The CycloPlus cartridge filter stays cleaner and lasts longer than other models.The illustrations below show the CDK during collection and during cleaning. CDK during collection CDK during cleaningDUSKOLECTOR® APPLICATIONS The following information is designed as a guide for selecting the right DusKolector® for your application. The first consideration is the CFM required for each dust-producing machine. The minimum CFM required for popular types of machines is shown below. The data is in accordance with the Industrial Ventilation Manual. The volume, weight, and nature of the material being collected are other factors to be considered. In order to capture the dust, hoods or scoops must fit closely around the work point, and the DusKolector® should be located as close as possible. Duct runs should have a minimum of elbows, bends and vertical rises. Proper ductwork is important to provide maximum efficiency. METALWORKING OPERATIONSPedestal Grinder wheel diameter up to: 9" 16"19" 24" 30" wheel width: 1-1/2"2" 3" 4"5" minimum CFM: 220 390 500610 880Buffing or Brushing Operationwheel diameter up to: 9" 16"19" wheel width: 2"3" 4" minimum CFM: 300 500 610Abrasive Belt Contact Wheel Grinderbelt width up to: 1-1/2" 2" 3"4" 5" 6"minimum CFM: 220 390 500 610 880 1200Abrasive Belt Platen Grinder belt width up to: 3"5" 7" 9" 11" 13"minimum CFM: 220 300 390 500 610740 WOODWORKING OPERATIONSBand Saw blade width: 2"3" 4" 5"6" minimum CFM at intake: 350 350 550 550 550 minimum CFM at end of duct:350 550 800 1100 1400 Jointer knife length: 6" 12" 20" over 20" minimum CFM: 350440 550 800 Table Sawsaw diameter: 16"20" 24" minimum CFM: 350 440 550CFM vs. STATIC PRESSUREHammond DusKolector® CFM and static pressure ratings are arrived at by following the Air Movement and Conditioning Association test code procedures. The chart below is useful for complex, multiple machine installations. Total external static pressure is determined by hood entry loss; length of straight duct; and number of elbows and branch entries. For simpler applications, refer to the Maximum Collection Capacity for each DusKolector® model. ModelInlet Diameter (inches)CFMExternal Static PressureVelocity FPMBags or TubesCloth Filter Area (sq.feet)DK-4 4 500 400 350 | |||||||||

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید