NPM_W0 pages

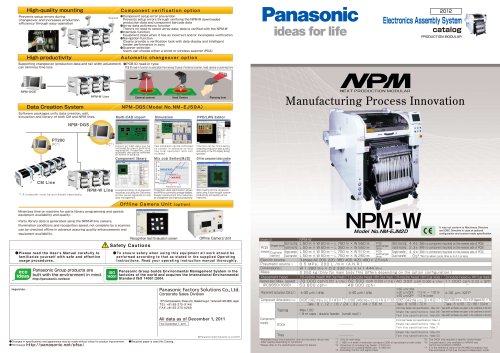

;h-quality mounting

nnnnPrevents setup errors during

nnnnchangeover and increases production

nnnnefficiency through easy operation

nnnns •Component setup error prevention

nnnnscanner prevents setup errors through verifying the NPM-W downloaded

nnnnproduction data and component barcode data

nnnn% ©Array data activesync function

nnnn:m There's no need to select array data; data is verified with the NPM-W

nnnn•Interlock function

nnnnEquipment stops when it has an incorrect and/or incomplete verification

nnnn•Navigation function

nnnnClearly provide a verification task with data display and intelligent

nnnnfeeder performance in sync

nnnn•Scanner selection

nnnnUsers can choose either a wired or wireless scanner (PDA)

nnnnutomatic changeover option

nnnnSupporting changeover (production data and rail

nnnncan minimize time loss

nnnnwidth adjustment) •PCB ID read-in type

nnnnPCB ID read-in function is selectable from among 3 types of external scanner, head camera or planning form

nnnnNPM-DGS

nnnnData Creation System

nnnnSoftware packages unify data creation, edit,

nnnnsimulation and library of both CM and NPM lines.

nnnnGS(Model No.NM-EJS9A)

nnnnMulti-CAD import

nnnnSimulation

nnnnPPD/LWS Editor

nnnnPT200

nnnnPC*1

nnnn^\ - CM Line

nnnn*1:A computer must be purchased separately.

nnnnAlmost all CAD data can be

nnnnretrieved by macro definition

nnnnregistration. Properties, such

nnnnas polarity, also can be confirmed

nnnnon screen in advance.

nnnnTact simulation can be confirmed

nnnnon screen in advance so that

nnnnline total operation ratio can

nnnnincrease.

nnnnComponent library Mix Job Setter(MJS)

nnnn1 | ||

NPM-W Line A component library of all placemenl

nnnnmachines including the CM series

nnnnon floor can be registered to unify

nnnndata management.

nnnnTime loss can be minimized by

nnnncompiling production data quickly

nnnnand easily on the PC display during

nnnnoperation.

nnnnOff-line component data creation

nnnnoption

nnnnProduction data optimization allows

nnnnthe NPM to commonly arrange feeders.

nnnnFeeder replacement time reduction

nnnnfor changeover can improve productivity

nnnnWith creating off-line component

nnnndata using a store-bought scanner,

nnnnproductivity and quality can be

nnnnimproved.

nnnnOff

nnnnera Unit (c

nnnnMinimizes time on machine for parts library programming and assists

nnnnequipment availability and quality.

nnnnParts library data is generated using the NPM-W line camera.

nnnnIllumination conditions and recognition speed, not complete by a scanner,

nnnncan be checked offline in advance assuring quality enhancements and

nnnnequipment availability.

nnnnRecognition test/Evaluation screen

nnnnOffline Camera Unit

nnnn^Safety Cautions | |

• Please read the User's Manual carefully to familiarize yourself with safe and effective usage procedures. | • To ensure safety when using this equipment all work should be performed according to that as stated in the supplied Operating Instructions. Read your operating instruction manual thoroughly. |

Panasonic Group products are lr«Kfifjf Duilt witn tne environment in mind. ^■■■■0^ http://panasonic.net/eco/ | Panasonic Group builds Environmental Management System in the P7*fl factories of the world and acquires the International Environmental UiiU Standard ISO 14001:2004. |

Panasonic Factory Solutions Co., Ltd.

nnnnCorporate Sales Division

nnnn1375 Kamisukiawara, Showa-cho, Nakakoma-gun, Yamanashi 409-3895, Japan

nnnnTEL +81-55-275-9148

nnnnFAX +81-55-275-6269

nnnnAll data as of December 1, 2011

nnnnVer.December 1, 2011

nnnn©Panasonic Factory Solutions Co.,Ltd.2011

nnnn►Changes in specifications and appearance may be made without notice for product improvement.

nnnn►Homepage http://panasonic.net/pfsc/

nnnn►Recycled paper is used this Catalog.

nnnnPanasonic

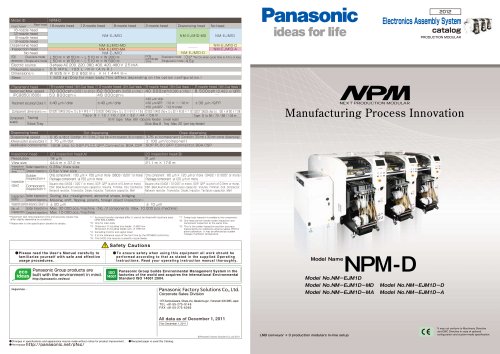

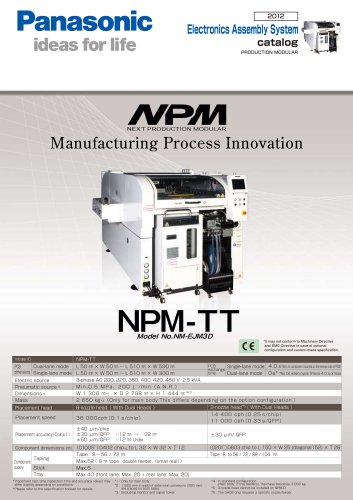

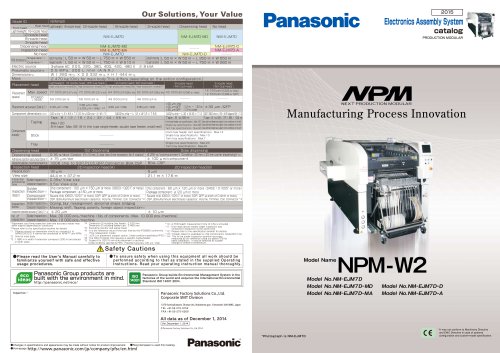

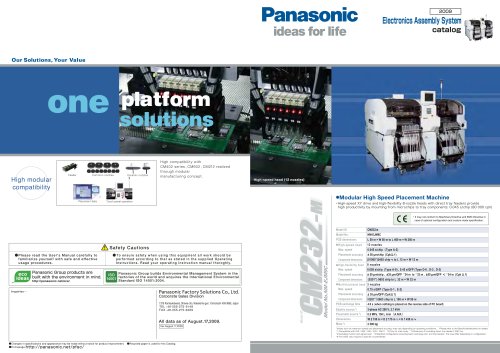

nnnn2012

nnnnElectronics Assembly System ..

nnnnideas for life

nnnnPRODUCTION MODULAR

nnnn/I/ROT

nnnnNEXT PRODUCTION MODULAR

nnnnManufacturing Process Innovation

nnnn. ■ ■-—

nnnnNPM-W

nnnnModel NO.NM-EJM2D

nnnn*lt may not conform to Machinery Directive

nnnnand EMC Directive in case of optional

nnnnconfiguration and custom-made specification.

nnnnNPM-W

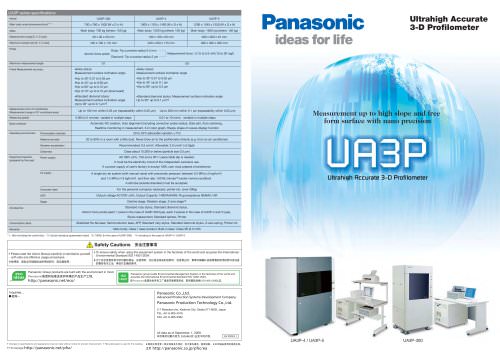

nnnnPCB dimensions | iBatch mounting | L 50 mm x W 50 mm ~ L 750 mm x W 550 mm | PCB exchange time | Batch mounting | 4.4 s (With no component mounted on the reverse side of PCB) | |

cjingie-iane | 2-positin mounting | L 50 mm x W 50 mm ~ L 350 mm x W 550 mm | 2-positin mounting | 2.3 s (With no component mounted on the reverse side of PCB) | ||

Dual-lane (option) | Single transfer | L 50 mm x W 50 mm ~ L 750 mm x W 510 mm | PCB exchange time | Single transfer | 4.4 s (With no component mounted on the reverse side of PCB) | |

Dual transfer | L 50 mm x w 50 mm ~ L 750 mm x w 260 mm | Dual transfer | 0 S* *No 0s when cycle time is 4.4 s or less | |||

Electric source | 3-phase AC 200, 220, 380, 400, 420, 480 V 2.5 kVA | |||||

Pneumatic source *i | 0.5 MPa. 200 L /min (A.N.R.) | |||||

Dimensions*! | W 1 280 mm*2 x □ 2 332 mm*3 x H 1 444 mm*4 | |||||

Mass | 2 250 kg (Only for main body:This differs depending on the option configuration.)_ | |||||

Placement head

nnnn16-nozzle head (With Dual Heads) 12-nozzle head (With Dual Heads) 8-nozzle head (With Dual Heads) 3-nozzle head -e( With Dual Heads)

nnnnMax. speed

nnnnIPC98500608)

nnnn70 000 cph(0.051 s/chip) 62 500 cph(0.058 s/chip) 40 OOP cph(0.090 s/chip)

nnnn53 800 cphv_48 OOP cph'?__—_

nnnn1 1 PPO cph (0.33 s/QFP)

nnnnPlacement accuracy(Cpk£ 1

nnnn:40 A/m/chip

nnnn:40 yum/chip

nnnn±40 ym/chip

nnnn±30 ym/QFP

nnnn±50 /jm/QFP

nnnn□12r

nnnn□12 r

nnnni ~ Q32 n

nnnniUnder

nnnn:30 ym /QFP

nnnnComponent dimensions (mm)

nnnnTaping

nnnnComponent

nnnnsupply

nnnn(01005")0402chip's toL6xW6xT3

nnnnTape : 8 / 1 2 / 1 6 / 24 / 32 / 44 / 56

nnnnMax. 120

nnnn( 8 mm tape : double feeder, (small real))

nnnn')0402 chip'5 to L12 x W12 x T 6,5 (01005") 0402 chip % to L 32 x W 32 x T 12 (0201")0603 chip to L150 x W 25 (diagonal 152) x T 281

nnnnStick

nnnnTray

nnnn•Placement tact time.inspection time and accuracy values may

nnnndiffer slightly depending on conditions

nnnn* Please refer to the specification booklet for details.

nnnnOnly for main body

nnnn1 880 imi in width if extension conveyors (300 m) are placed on both sides.

nnnnDimension D including tray feeder: 2 570 mm

nnnnDimension D including feeder cart: 2 465 mm

nnnnExcluding monitor and signal tower

nnnnTape: 8 to56/72mm_Tape:8 to56/72/88/104mm

nnnnFront/rear feeder cart specifications: Max. 120 (Tape width and feeder are subject to the conditions on the left)

nnnnSingle tray specifications : Max.86 (Tape width and feeder are subject to the conditions on the left)

nnnnTwin tray specifications : Max.60 (Tape width and feeder are subject to the conditions on the left)

nnnnFront/rear feeder cart specifications: Max. 14

nnnnSingle tray specifications : Max. 10

nnnnTwin tray specifications : Max.7

nnnnSingle tray specifications : Max.20

nnnnTwin tray specifications : Max.40

nnnn*5 : The 0402 chip requires a specific nozzle/feeder.

nnnn*6 : 3-nozzle head is only available to NPM-W and

nnnncannot be installed to NPM-D.

nnnn*7 : It is the reference value of an IPC9850-compliant tact

nnnntime estimated in the dual conveyor/independent mode.

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید