thik film technology0 pages

R&D BULLETIN

THICK FILM TECHNOLOGY

Thick film technology is simply a technique for

applying a layer of material onto a substrate.

Layer thickness can be varied from 5 to several

hundred microns but typically are about 25.

Thick film technology is widely used in the

electronic industry for the preparation of hybrid

circuits.

Thick film layers are applied and processed in

powder form. The layer material is mixed with

polymer and glass binders, used to give the thick

film layer both strength and adhesion to the

substrate and temperature depending electric

properties. A heavy organic solvent is also added

to form a thick film ink of a viscosity suitable for a

screen printing process.

The ink is printed as an image through a mesh

screen onto the substrate, dried to remove most of

the organic medium (100°C-200°C) and fired

(450°-900°C) to form a continuous layer with

specific electrical behaviour and tolerances.

A layer containing Ag/Pd, Ni/Cr, Mo or C powders

printed in the form of a resistive track onto an

insulating substrate has potential applications as a

heating element.

The ink composition governs both the electric

(O/sq and TCR) and mechanical (adhesion, TCE)

behaviour of the thick film layer.

By changing the powder composition, dielectric or

conducting areas can be printed as well.

By selection of the binder material and processing

conditions it is possible to apply several thick film

layers onto many different substrates, including

300 and 400 series stainless steel, aluminium,

ceramics, glass and mica foils.

Printable shapes may be both flat and circular.

Cermet and polymer thick film heating elements

have several attractive properties including thin

section, direct application to the surface to be

heated, rapid response, high power density

support, flexible design and power pattern,

NTC/PTC control integration. Multiple heating

elements and varying power outputs can be

incorporated across a single substrate in order to

get the requested temperature distribution.

Max temperature of operation depends upon the

substrate and the dielectric thickness, ranging

from 200°C up to 600°C.

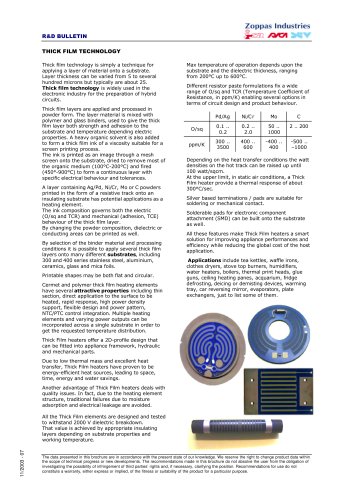

Different resistor paste formulations fix a wide

range of O/sq and TCR (Temperature Coefficient of

Resistance, in ppm/K) enabling several options in

terms of circuit design and product behaviour.

Pd/Ag

Ni/C r

Mo

C

O/sq

0.1 ..

0.2

0.2 ..

2.0

50 ..

1000

2 .. 200

ppm/K

300 ..

3500

400 ..

600

-400 ..

400

-500 ..

–1000

Depending on the heat transfer conditions the watt

densities on the hot track can be raised up until

100 watt/sqcm.

At the upper limit, in static air conditions, a Thick

Film heater provide a thermal response of about

300°C/sec.

Silver based terminations / pads are suitable for

soldering or mechanical contact.

Solderable pads for electronic component

attachment (SMD) can be built onto the substrate

as well.

All these features make Thick Film heaters a smart

solution for improving appliance performances and

efficiency while reducing the global cost of the host

application.

Applications include tea kettles, waffle irons,

clothes dryers, stove top burners, humidifiers,

water heaters, boilers, thermal print heads, glue

guns, ceiling heating panes, acquarium, fridge

defrosting, deicing or demisting devices, warming

tray, car reversing mirror, evaporators, plate

exchangers, just to list some of them.

Thick Film heaters offer a 2D-profile design that

can be fitted into appliance framework, hydraulic

and mechanical parts.

Due to low thermal mass and excellent heat

transfer, Thick Film heaters have proven to be

energy-efficient heat sources, leading to space,

time, energy and water savings.

Another advantage of Thick Film heaters deals with

quality issues. In fact, due to the heating element

structure, traditional failures due to moisture

adsorption and electrical leakage are avoided.

11/2003 - 07

All the Thick Film elements are designed and tested

to withstand 2000 V dielectric breakdown.

That value is achieved by appropriate insulating

layers depending on substrate properties and

working temperature.

The data presented in this brochure are in accordance with the present state of our knowledge. We reserve the right to change product data within

the scope of technical progress or new developments. The recommendations made in this brochure do not absolve the user from the obligation of

investigating the possibility of infringement of third parties’ rights and, if necessary, clarifying the position. Recommendations for use do not

constitute a warranty, either express or implied, of the fitness or suitability of the product for a particular purpose.

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید