Duplex Filter0 pages

DN 25 - 150 DN 25 - 150

nnField of application

Standard design Special design or supplementary equip-ment respectively >

nnFilter insert

DN 25-40 basket strainer DN 50-150 ring strainer Ring strainer / double strainer Basket strainer / pleated basket strainer >

nnFilter fineness

80 - 1000 m: cloth with support plate (please refer to Page No. 6.1) > 1mm a perforated plate with a circular perforation 10 - 60 յm >

nnFilter lock

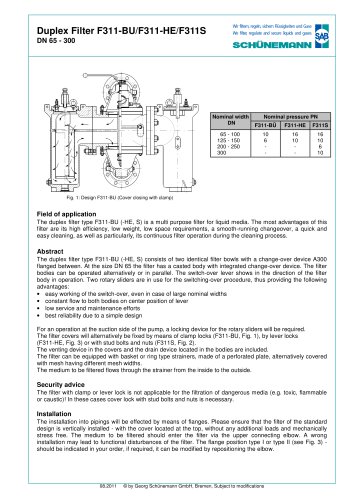

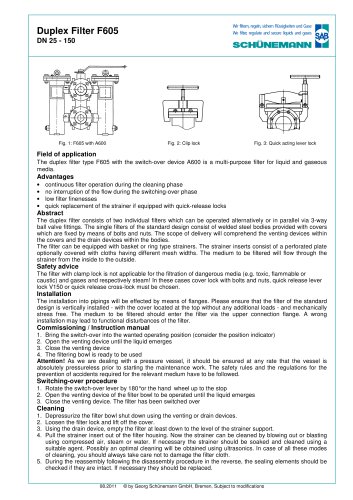

Through bolts with nuts Fig. 1: F 605 with A 600 DN 25 - 50 Clip lock (Fig. 2) DN 32 - 100 Quick acting lever lock (Fig. 3) DN 80 - 100 Quick-release cross lock Fig. 2: Clip lock Fig. 3:Quick acting lever lock The double filter, type F 605, with the fitting A 600 is a multi-purpose filter for gaseous, liquid and pasty media. Advantages: >

nnVenting device

Bolt Cock continuous filter operation during the cleaning phase >

nnDraining device

Bolt Cock no interruption of the flow during the switching-over phase >

nnConnection

According to the design pressure of the filter, flanges DIN 2632/33 According to the customers specification high filter finenesses quick replacement of the strainer if equipped with quick-release locks >

nnMaterials Abstract

Housing and Cover St 35.8/P265 GH, 1.4541 1.4571 The double filter consists of two individual filters which can be operated alternatively or in parallel via 3-way ball cock fittings. The sin-gle filters of the standard design consist of welded steel housings provided with covers which are fixed by means of bolts and nuts. The scope of delivery will comprehend the venting device within the cover and the draining device within the housing. The filter can be equipped with basket or ring strainer inserts. The filter inserts consist of a perforated plate optionally covered with cloths having different mesh widths. The medium to be filtered will flow through the strainer from the inside to the outside. Filter lock According to the housing material 1.4571 Cover sealing (O-Ring) Flat packing, free of asbestos O-ring: buna N, viton, EPDM, PMQ, teflon Perforated plate/cloth St, St/1.4401, 1.4301, 1.4301/1.4401 1.4571, 1.4571/1.4401, Hastelloy C 4, vari-ous synthetic materials >

nnInstallation

Switch-over device 1.0619/1.4408/TFM-25% Glas/FPM 1.4571/1.4408/TFM-25% glas/FPM The installation into pipings will be effected by means of flanges. Please ensure that the filter of the standard design is vertically in-stalled - with the cover located at the top without any additional loads - and mechanically stress free. The medium to be filtered should enter the filter via the upper connecting elbow. A wrong installation may lead to functional disturbances of the filter. The (flange position - type I or type II (see Fig. No. 3) - should be indicated in your order but, if required, it can be modified by reposition-ing the elbow. Vent valve - - Air relief cock - Nickeled steel, St, A4 Vent screw A4 - Drain plug A4 - >

nnCommissioning

1. shift the switch-over lever into the operating position. 2. open the venting device until the liquid emerges. 3. close the venting device. The filtering jug is ready to be used Drain cock - Nickeled steel, St, A4 >

nnAdditional filter

- Magnet filter insert (see Page. xxx) >

nnHeating

- Steam, hot water or electric heating - for sea water filters see page xxx >

nnSwitching-over procedure Zinc protection

1. Rotate the switch-over lever by 180Ұ or rotate the hand wheel up to the stop. 2. Open the venting device of the filtering jug to be operated until the liquid emerges. 3. Close the venting device. The filter has been switched over. >

nnDifferential pressure meter

- Optical, electrical (see page xxx) >

nnSurface treatment

At the inside: >

nnCleaning

1. Depressurize the filtering jug shut down using the venting or draining devices. 2. Loosen the filter lock and lift off the cover. 3. Using the draining device, empty the filter at least down to the level of the strainer support. 4. Pull the strainer insert out of the filter housing. Now the strainer can be cleaned by blowing out or blasting using compressed air, steam or water. If necessary the strainer should be soaked and cleaned using a suitable agent.. Possibly an optimal cleaning will be obtained using ultrasonics. In case of all these modes of cleaning, you should always take care not to damage the filter cloth. 5. During the reassembly following the disassembly procedure in the reverse, the sealing elements should be checked if they are intact. If necessary they should be replaced. Housing: steel Preservation oil Anti-corrosion protection enamel, epoxy resin, rubber, E-OTFE Housing: stainless steel Pickled and passivated Glass bead blasted At the outside Housing: steel: Synthetic enamel RAL 5018, turquoise - Housing: stainless steel Pickled and passivated Glass bead blasted >

nnHeating system

(Suffix of the type designation code: ......................H) As a starting aid and in order to achieve a permanent decrease of the viscosity of the medium to be filtered, the filter can additionally be equipped with a heating system. The heating system will be designed as steam or hot water dome heating system or as an electric heating system respectively which can be supplied in steel or A 2 and which will have a flange connection DN 15 or an Ermeto coupling respectively. Further-more, we would like to offer you a steam heating as a On customer`s request further design and material variants will be manufactured and supplied. Please let us have your relevant inquiry. heating system within the outer mantle . Upon request we shall let you have the data of this particular design. 11.2003 by Georg Schɼnemann GmbH, Bremen, Subject to modifications 11.2003 by Georg Schɼnemann GmbH, Bremen, Subject to modifications >

"

عضویت

عضویت  ورود اعضا

ورود اعضا راهنمای خرید

راهنمای خرید